A simple but effective treatment to help prevent clogging in irrigation lines has returned a leading Kent raspberry grower’s system to peak performance.

As a supplier to some of the UK’s best-known supermarkets, the team at Kelsey Farms is tightly focused on achieving top yields of Class 1 quality fruit to optimise already finely balanced margins.

Accurate irrigation is key across the 47ha of raspberries grown for premium markets on the main farm at Wickhambreaux and in the 10ha raspberry nursery.

The entire crop is grown in polytunnels in individual pots of coir, each with a dripper that delivers the necessary water and nutrients.

The irrigation system is computer-controlled to aid accuracy, linked to sensors placed in some pots to reduce the risk of over-watering and over-feeding. However, maintaining dosing within acceptable limits in some areas was becoming difficult.

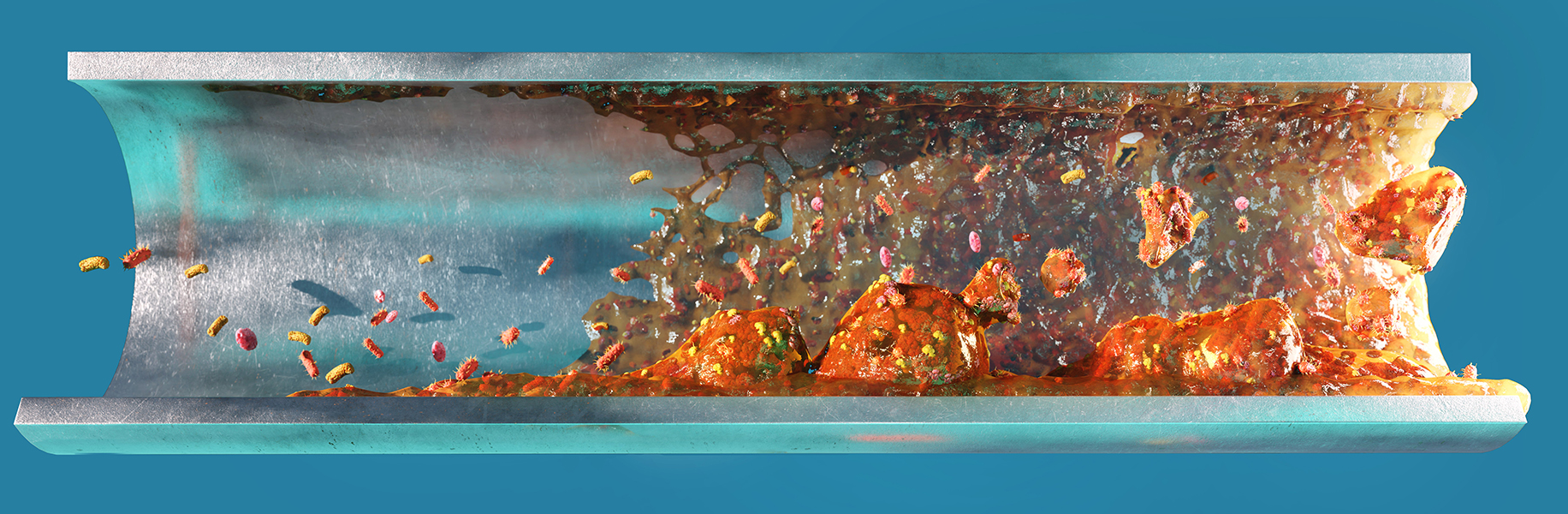

Adam Cannon, irrigation manager at Kelsey Farms, says: “We were continually getting blockages in the drip line and pressure drops in the main line due to the build-up of biofilm, caused by algae and other little nasties. Pathogens were also a problem.

“As biofilm built up, water application was affected – some roots were drowning and others were left too dry. The end result was low yields of soft misshapen fruit.

“It’s difficult to put a figure on lost output, but it was having an effect. Trying to keep lines clear was also time-consuming and costly; we have 800,000 drippers and 285,000m of pipe. In 2022 we renewed around 25,000 drippers due to blockages, just over 3%, all which were changed by hand on a regular basis.”

Adam Cannon, irrigation manager at Kelsey Farms

Adam Cannon, irrigation manager at Kelsey Farms

The following season Adam’s agronomist, Simon Warren from Agrovista, contacted Nigel Bennet, technical support manager for Roam Technology, which manufactures Huwa-San TR-50 silver stabilised hydrogen peroxide, a highly effective disinfectant and biocide.

“Nigel had already approached me about the potential benefits of the product for the soft fruit sector, so we decided to give it a go,” says Simon.

“Huwa-San has worked well for our glasshouse division, with a number of growers using the product for various disinfection processes, including season-long biofilm control in irrigation systems.

‘’As well as causing blockages, biofilm also harbours pathogens, including bacteria, fungi and oomycetes, which can multiply and infect plants. Phytophthora had started to affect some plants, which was the initial reason for taking action at Kelsey Farms.

“Huwa-San will neutralise all these problems. It persists in the system much longer than standard hydrogen peroxide, increasing its efficacy, so it can be used at lower doses.

“Clear irrigation lines are important in any protected crop, but are vital with raspberries, which are very sensitive to over-or under-dosing.”

Nigel carried out a preliminary visual inspection that revealed high levels of microbial growth in the irrigation system. He then carried out a full site survey. Recommendations included siting a Huwa-San dosing pump in each of the eight irrigation rigs (pressure pump plus associated pipework) on the main farm and a further three in the nursery.

“Biofilm is an all-too-common problem in irrigation systems and the key is to eradicate it quickly and efficiently,” says Nigel. “Huwa-San is applied automatically using a user-friendly fit-and forget system that is pretty straightforward to install.

“Biofilm is an all-too-common problem in irrigation systems and the key is to eradicate it quickly and efficiently,” says Nigel. “Huwa-San is applied automatically using a user-friendly fit-and forget system that is pretty straightforward to install.

“Usually we start by shock-dosing the system at the end of the season, but this was mid-crop. So we applied a standard continuous dose of 40-50ml per cubic metre of water, and flushed the system regularly to remove any biofilm residue.”

Subsequent hydrogen peroxide test strips at the drippers showed Huwa-San was evenly distributed throughout the system at the right concentration. Water testing revealed a zero-pathogen count.

Introducing the product has helped dramatically, Adam confirms. “We’ve had a whole season using Huwa-San. The mix and fertigation tanks are all much cleaner and dripper blockages are now very rare.

“We now clean in-line filters once a week rather than daily, while flow sensors on the main line are cleaned monthly not weekly.

“We’ve saved a lot of time and money and we are getting more even application of water and fertiliser products. Plant growth and fruit size is more even, producing more uniform yields and better quality.

“I would 100% recommend Huwa-San to other growers – we wouldn’t be without it now.”