Adopting a highly cost-effective variable rate nitrogen application system has resulted in more even crops and looks set to deliver better yields for one Yorkshire farming business.

James Robinson is no stranger to satellite farming, having used a GPS guidance system for the past six years across the 221ha South Farm he runs with his father at Sunk Island near Hull.

While he has appreciated the direct cost benefits of more accurate machinery use, he is now widening his use of space-age technology, starting down the journey of variable rate input applications last season.

He and his agronomist, Agrovista’s Tom Abbott, noticed that the combine’s yield maps were showing some variation across fields, despite relatively uniform silty clay soils.

After discussion with Agrovista’s Precision team, they decided to try variable nitrogen applications to improve nitrogen use efficiency and hopefully produce more even crops.

“We are fairly confident that other factors such as pH, P and K are OK, and we aren’t aware of any other issues such as soil structure problems would result in the sort of crop variation the yield maps were picking up,” says James.

“I didn’t really want to spend too much money analysing soils at this point, so the suggestion was we try targeting nitrogen applications as a first step.”

Application maps

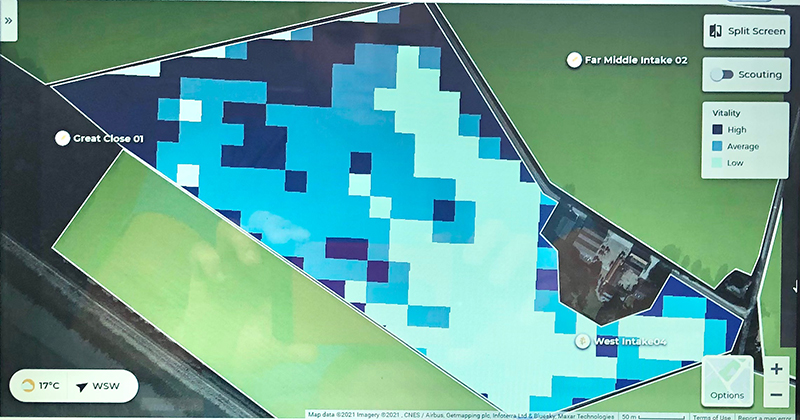

Nitrogen application maps are based on data from biomass maps recorded by satellites every few days as well as from yield maps recorded at harvest, cleansed by Agrovista Precision to remove clutter and ensure data was representative.

By crunching both sets of data, the software produces a zoned map of each field divided into good, satisfactory and poor areas.

Graeme Barrett, Agrovista’s Precision manager, says: “The aim is to feed crops more efficiently, applying nitrogen in line with crop potential. Once we have the application maps in front of us, we ask growers how much they want to vary the rate.

“Growers know their farms and generally have a good idea of the optimum nitrogen level, so base their thoughts on that.

“We generally find that most growers opt for 5-10% in their first year, but increase as they gain confidence in the system.”

James decided to drop the level on the high biomass areas by 10%, increasing rates on more sparse areas by the same amount while leaving the mid-range unchanged.

“Our yields historically vary from 8-11t/ha, and our thinking was that poorer areas would respond to increased nitrogen rates but the higher yielding areas would not, as they were already at the upper end of rates.”

Once the information has been loaded into the system, the necessary data can be downloaded onto an Android tablet that connects to the Agrovista Machine Control (AMC) variable rate controller from the tractor cab.

“It’s simplicity itself,” says James. “You connect up, set up for the appropriate field, and off you go. It’s pretty impressive to see how application rates vary as you drive along, and how it coincides exactly with the maps, which are displayed on the tablet in front of me.”

Wheat crops appeared to be more even following the variable rate treatment and this was confirmed by comparing 2021 and 2020 yield maps. “Applying nitrogen rates more in line with crop need has certainly had a beneficial effect,” says James.

“Overall, total nitrogen use has scarcely changed. However, while the weather helped massively in improving wheat yield in 2021, I believe part of that increase was down to the variable rate nitrogen.

“There was no change in seed rate or seed dressing to previous years. With the variable nitrogen, we noticed that there was a more even yield across the fields.

“Whether we increase the percentage variability remains to be seen – we are going to discuss this with Tom.”

The service costs just £4.30/ha, plus the small initial cost of the AMC that was retrofitted to the farm’s Amazone Z-AM twin-disc fertiliser spreader.

On average, customers who adopt variable rate N achieve a 3-5% yield advantage, worth £36-£60/ha on an 8t/ha wheat crop priced at £150/t.

“It is a good way of manipulating growth to improve returns – it doesn’t take much of a yield increase repay the initial costs,” says Graeme.

Agrovista’s service has been impressive, says James. “They helped to get the system working really quickly.

“We’ve ended up with a system that is applying fertiliser more accurately than I could hope to. It works really well, and we have access to all the data and live updates so we know exactly what’s going on and what we’ve done.”

James Robinson

C G Robinson & Son

South Farm, Sunk Island, Hull

Farm size: 221ha

Soils: silty clay

Cropping: wheat x3, barley, oilseed rape (spring cereal option to aid blackgrass control)

Cultivations: rotational ploughing, subsoil, disc/tine cultivator, power harrow